Antimicrobial Treatment

Preventing harmful bacteria in the food manufacturing industry

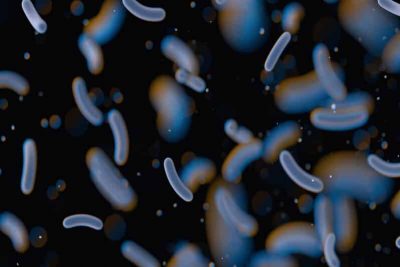

Antimicrobial treatments kill bacteria

Antimicrobial treatments are used to kill or slow down the spread of bacteria. As we’re not able to see microorganisms with the naked eye, food manufacturing plants require specialised chemicals to remove the danger of contamination.

Bacteria in food manufacturing occurs when protein builds on surfaces. All surfaces are prone to bacterial growth – floors, walls, ceilings, benches and manufacturing equipment. Surfaces prove to be breeding grounds for potentially hazardous bacteria called biofilm.

Biofilm is a severe threat to your production lines but our effective antimicrobial treatments sanitise and disinfect all surfaces and manufacturing equipment, killing a wide range of microbes.

Book a site visit & quote

If you’d like us to quote on a job, fill in this form, and we’ll get back to you and arrange a time for a site visit.

"*" indicates required fields

All food manufacturing plants should undergo antimicrobial treatments to prevent the spread of contamination that could pose a serious risk to consumer health. Listeria, salmonella, E. coli and many more harmful bacteria are removed during an antimicrobial treatment.

The food processing industry is one of the most challenging industries in New Zealand. With our high standards of hygiene, food manufacturers have numerous stringent rules to adhere to for compliance.

There is no one size fits all solutions for antimicrobial treatments as no two food processing plants are alike. We cannot stress how important it is to schedule professional antimicrobial treatments to guarantee your food processing plant is hygienic and compliant at all times. Taking short cuts in the food manufacturing industry can have very nasty repercussions, not only for your business, but for your consumers.

The equipment and processes used vary greatly between manufacturers as each job has to be carefully assessed to ensure the correct treatment solutions are applied. We provide several options for antimicrobial treatments and our decision is based on a number of determining factors within your plant.

Sanitisers are the most common antimicrobial treatments used as they disinfect all surfaces to kill bacteria that could be a threat to your entire production. Bacteria multiplies at a rapid rate, so it’s critical to stop bacteria form creating biofilms where they colonise.

Talk to our specialist technical advisers today about suitable antimicrobial treatments for your food or beverage manufacturing environment.

We cater to all facets of food and beverage manufacturing and we have vast experience in treating the following:

- Bakeries

- Meat and poultry processing plants

- Dairy factories

- Wineries

- Breweries

- Snack manufacturers

Regardless of the amount of pipes, vents or confined spaces throughout your manufacturing premises we can treat all areas effectively. With regular scheduled antimicrobial treatments, peace of mind knowing your plant is producing clean, hygienic food, is invaluable.

"Whatever we do or wherever we go, our motto remains the same – we do what others can’t or won’t do"

You owe it to your consumers to schedule regular routine antimicrobial maintenance treatments and to give you peace of mind. Every food processing plant should have processes in place to ensure consistent and regular professional cleaning.

Every job is unique. And like all of the jobs our team undertake customisation is the key and the security you need to secure the best possible service from us.

Our team is available 24/7 and will work in with you to avoid disruption to your normal operations.