You may have heard of a deep clean, maintenance cleaning, disinfection, industrial and commercial cleaning – but have you ever heard of a ‘dry clean’?

Industrial cleaning has many intricacies involved that include specialist techniques, methods, and processes. What industrial cleaning type suits you and your company will depend on your individual requirements for the clean. One of these methods not often heard of is called a dry clean. And no, that’s not drying your clothes or anything to do with a laundry service.

What is an industrial dry clean service?

A dry clean service removes dust, dirt, and grime without the use of liquid so it’s a non-liquid clean. A dry clean or surface clean is a speciality process of cleaning, commonly used in dry processing or manufacturing plants and speciality food production plants.

Food production and manufacturing plants need to be kept hygienic and in pristine condition. One of the challenges with this type of cleaning is that liquids can’t be used during the cleaning process. This is because any liquid or moisture may affect the quality of the food or produce within the plant.

Who needs a dry clean service?

Our team is involved with the regular cleaning of one of the largest goat milk infant formula plants in the country.

We have completed plenty of dry cleans in canning and distribution manufacturing plants, which requires specialist knowledge, attention to detail, and careful planning.

The complexities of a dry clean

During these complex and challenging jobs, there are a series of processes and procedures our team goes through to ensure the highest level of cleanliness and quality.

We also go the extra mile to ensure that there is minimal disruption to the operations of the plants and manufacturing.

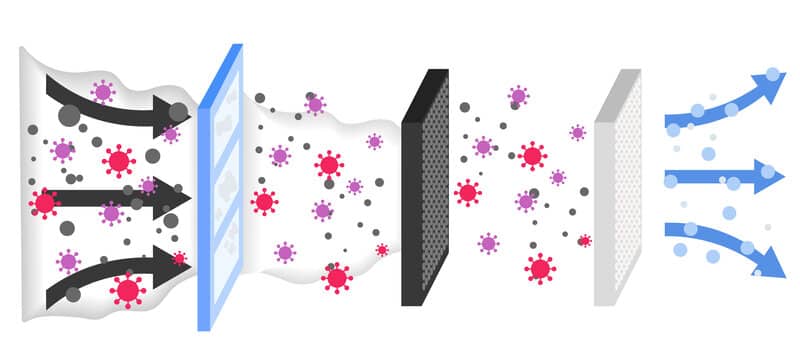

Specialist equipment is vital as well to ensure no contamination, especially for a high-level clean. Our team uses HEPA (High Energy Particle Absorber) filtered vacuum cleaners. Hepa filters are designed specifically for more complex cleaning work.

The HEPA filters must satisfy certain levels of efficiency and meet a certain standard.

To be certified the HEPA air filter must remove at the very least 99.97% of particulate matter. In other words, the HEPA filters act just as a sieve does, except not much can get through at all.

The use of these filters also minimises the risk of a dust explosion which is a very real hazard when working within manufacturing and processing plants.

How does a dust explosion occur?

Several factors must be present for an explosion to occur and include but are not limited to:

- A combustible dust

- Oxygen

- An enclosed space

- An ignition source

A dust explosion is the rapid combustion of fine particles suspended in the air within an enclosed location. – Robovent

What are the different types of cleaning services for industrial plants?

There are many different cleaning methods and techniques used within industrial and commercial manufacturing or processing plants.

Often dry cleaning is used over wet cleaning or cleaning with liquids, as there is a lesser risk of contamination. When liquids are used in any form of cleaning in the food industries, their use must be controlled.

Depending what your operations are will determine the type of cleaning service or services you need. For example, there are regular deep cleans, dry cleans, and wet cleans (such as antimicrobial treatments) like we have already discussed, along with one-off or occasional cleaning such as audit cleaning.

Industrial plants and manufacturing plants are complex places. There are plenty of nooks and crannies, hidden areas, high-level areas, and specialist equipment and machinery required to carry out the work.

What should you look for when booking a dry clean?

Experience, training, and qualifications are key to ensuring you are getting a quality clean – but beyond that a comprehensive cleaning plan along with great communication are paramount.

Our team has dedicated divisions to all the different areas of speciality cleaning. No two food manufacturing or processing plants are the same and require a tailored plan to suit your business operations.

We are proudly IMPAC Prequal qualified and our professional staff are qualified, experienced, and trained exactly to carry out any job. We have a strong commitment to health and safety and take it seriously.

No matter how tricky, challenging, or complex your work or plant may be, our team will get the job done and get it done right. We offer a wide range of services, and if you are not sure what you require feel free to talk to one of our friendly team.

If you have a complex job or manufacturing plant that requires any commercial or industrial services then get in touch with us today.